The women's handbag manufacturing workshop, France (81)

Making bags in France today is the work of a handful of workshops scattered throughout our country. During a long and tortuous search, a mutual crush led us to a small workshop located in the heart of the Tarn countryside. Located in Graulhet, a town renowned for tanning lambskin (tawing) since the 19th century, the leather workshop that produces some of JULES & JENN women's handbags employs around twenty people.

The workshop and JULES & JENN

Believing in a brand that's just starting out is always a gamble: yet it's the one taken on by this workshop that chose us as much as we chose it. We regularly meet with the experienced artisans who work on each stage of the JULES & JENN bag manufacturing process: the pattern maker, the cutter, the assembler, the stitcher, and all the other meticulous little hands who work on our fashion accessories.

From the designer to the workshop manager, we discuss product development, material selection, production progress, and how to improve JULES & JENN bags together and transparently.

The making of the handbag

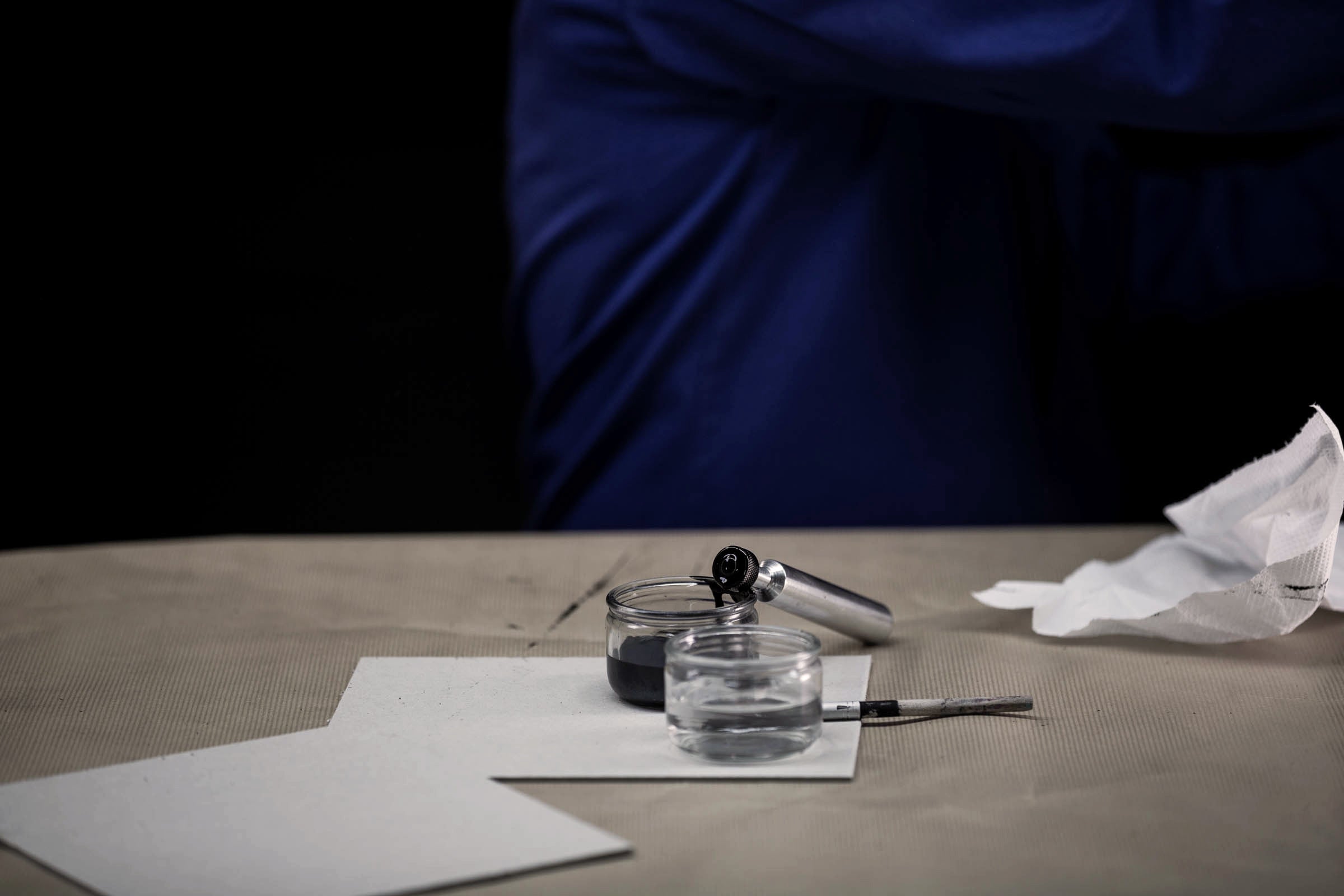

Based on the drawing, the pattern maker creates the pattern for the different parts that will make up the bag. Using punches, the cutter cuts out, manually or with a press, the different parts of the model in the chosen material. The pieces must be carefully cut to avoid natural defects in the leather. Each piece of leather is individually prepared according to the desired result: trimming the edges for sewing, threading, dyeing the raw-cut edges, gluing and drying the reinforcements, adding decorations. The pieces are then sewn together. Finally, the bag is pampered to remove the last traces and imperfections. Adorned with its JULES & JENN pouch, the bag is now ready to rest on your shoulder.

At a collection point from €25

Available in 3X, 4X

100 days to try

Email, phone