The small leather goods manufacturing workshop, Spain (Ubrique)

Our small leather goods workshop is located in the heart of Andalusia, in the small, white-washed town of Ubrique. At the foot of the mountains, this small town has successfully preserved its leatherwork tradition for decades, and today it still produces wallets for major French and international luxury brands.

While these prestigious brands have moved into ultra-modern buildings on the outskirts of the city, our workshop is located in the historic center, now pedestrianized. It's by wandering through a maze of streets that we discover this small team of passionate and experienced artisans.

The workshop and JULES & JENN

To find our small leather goods workshop, we naturally turned to Ubrique, a small town known worldwide for its wallet manufacturing for decades. And it was precisely on a workshop run by the 4th generation of leatherworkers that we chose. Surrounded by his two sons, the owner proudly tells us how his own grandfather created the workshop, then how his father significantly expanded it to employ around fifty artisans in the early 1980s, taking advantage of the boom in the accessories market. Suffering from the full force of Asian competition, the workshop had to bend its back and focus on its local customers. Today, with its 10 best artisans, sales are picking up again, thanks to the growing interest of European consumers in more local production.

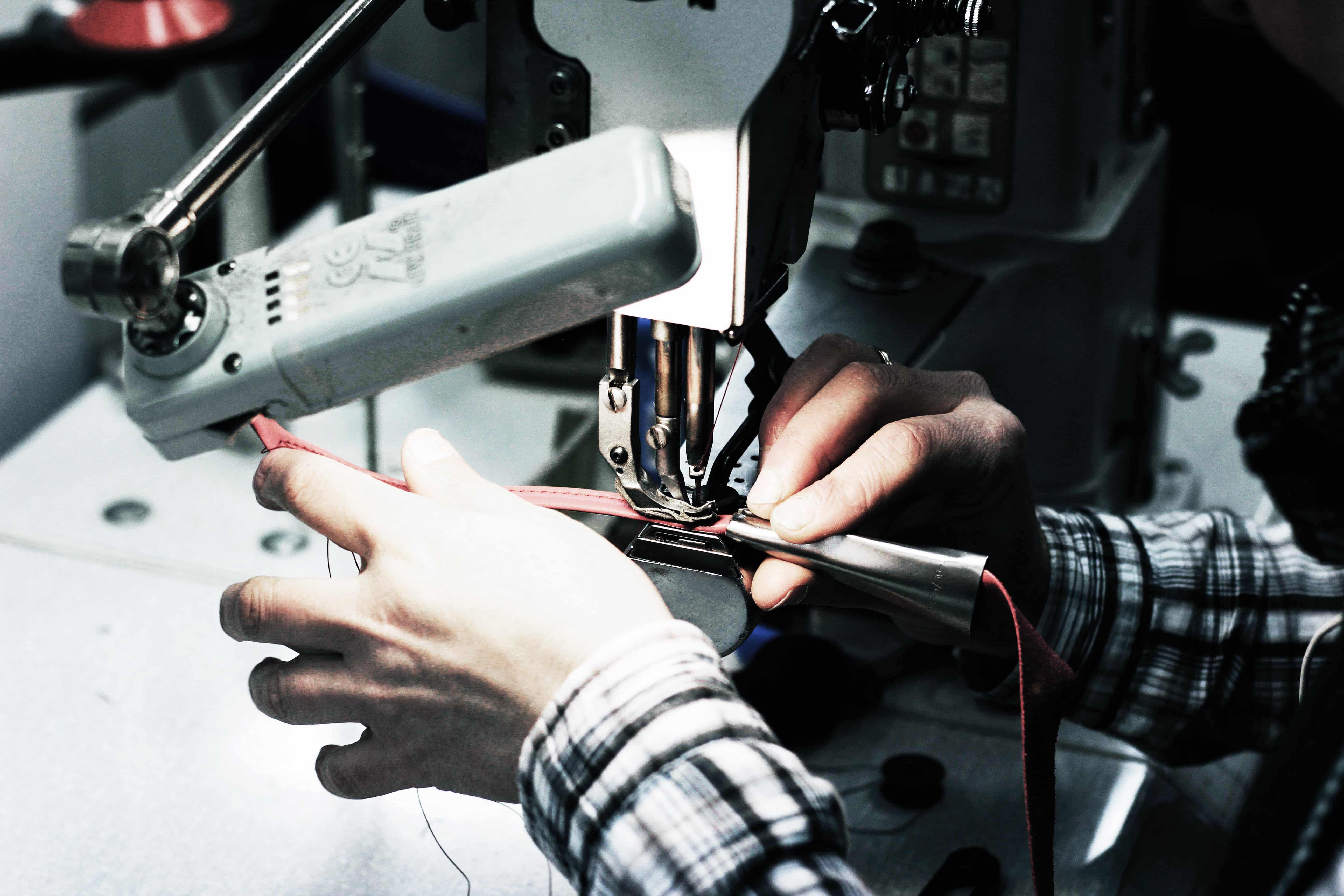

From our first exchanges, we were convinced by the responsiveness and quality of this workshop's work. Their mastery of assembly and stitching techniques, as well as the quality of the finishes, confirm that JULES & JENN small leather goods is in very good hands.

Making a wallet

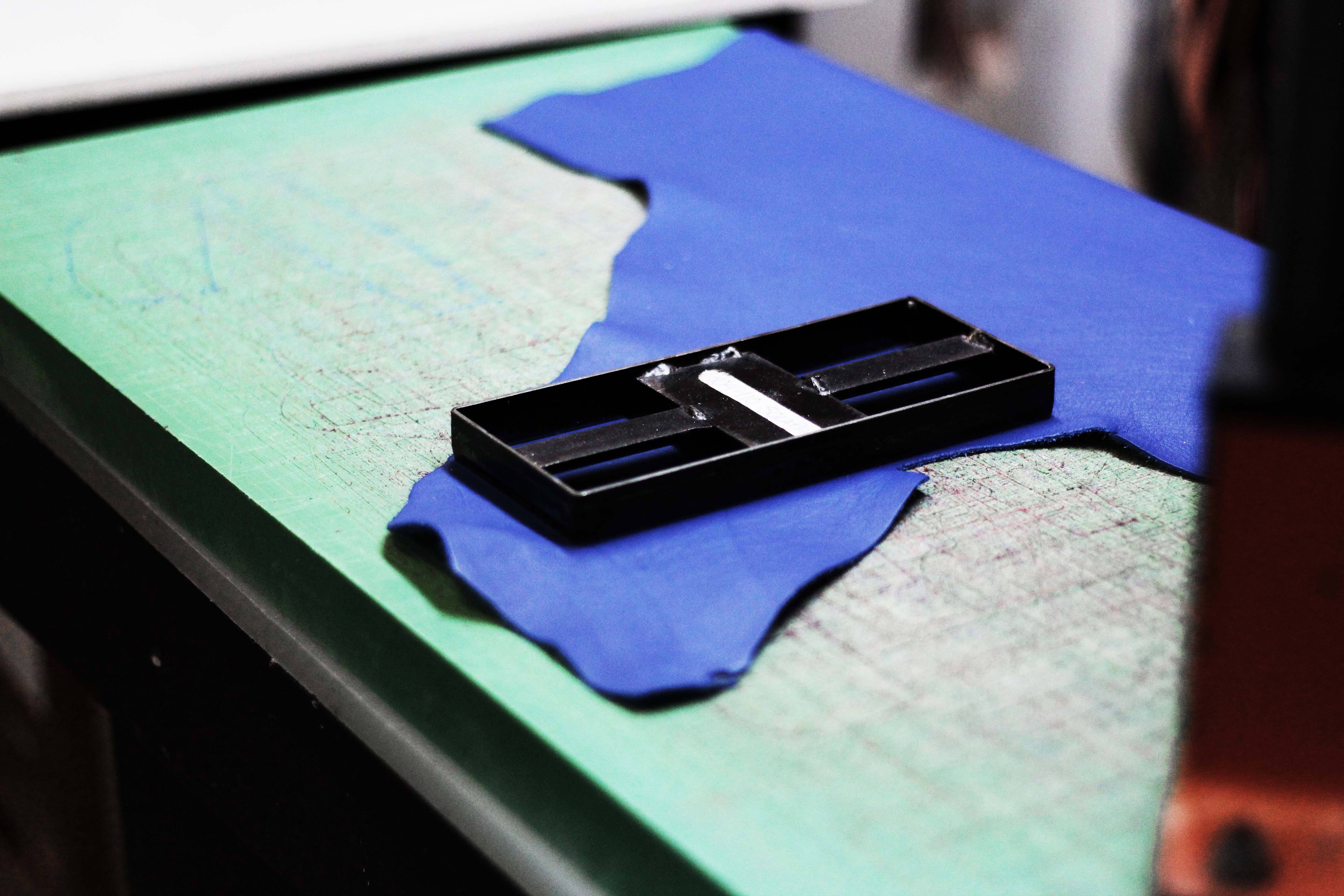

Based on the drawing, the pattern maker creates the pattern for the various parts that will make up the wallet. Each piece of cardboard is unique and represents each piece of material or reinforcement of the wallet. Two options are possible for cutting: with a cutter around the pattern pieces or with steel cutters used under a press. The pieces must be carefully cut to avoid natural defects in the leather.

In small leather goods, the key step is trimming the edges of all the pieces that need to be stitched. By giving the edges of the pieces the thickness of cigarette paper, the seams and edges are perfect. Other steps include filleting, dyeing the raw-cut edges, gluing, drying, adding decorations, and hot stamping. The pieces are then stitched together. Finally, the wallet is pampered for an impeccable finish before being tucked into its JULES & JENN box. Now it's ready to follow you in your bags and pockets, or to be given as a gift on any occasion.

At a collection point from €25

Available in 3X, 4X

100 days to try

Email, phone