The shoe-making workshop, Italy (Naples)

The workshop, located in Naples, was founded in the late 1930s and specializes in the production of leather shoes for women and men. Spanning the ages, it represents a balanced blend of craftsmanship and modernity, quality and choice of refined materials. Today, it is recognized as an expert in the Italian footwear industry.

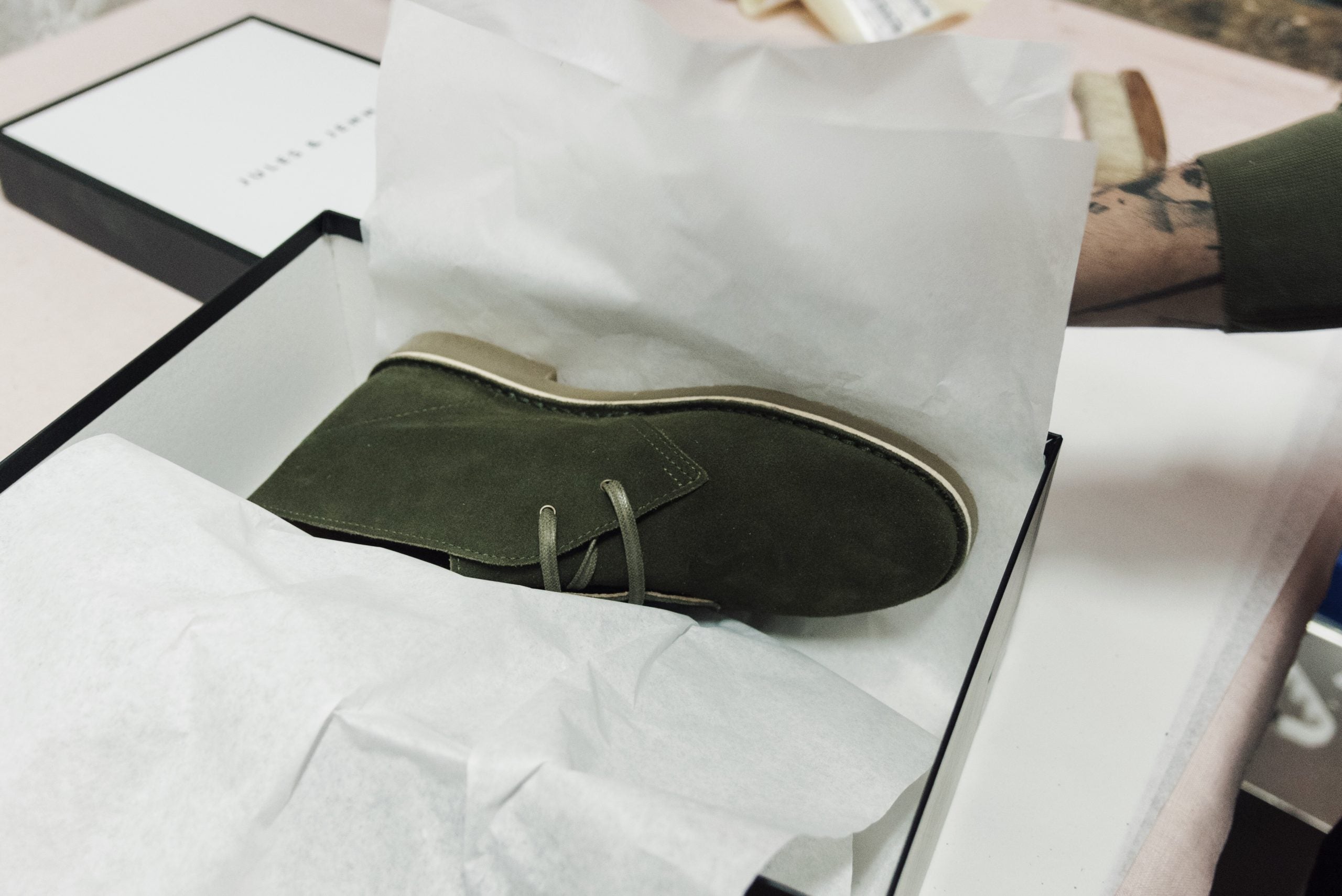

The workshop and JULES & JENN

The history of this shoe workshop began when the grandfather of the current managers created a wholesale center that brought together the excellence and know-how of the Campanian small laboratories. At that time, the favorable geographical position, in the center of the Mediterranean sea and on the route of the Suez Canal, and the mild climate made Naples the ideal destination for foreign investors, particularly in Northern Europe. The workshop thus broke into the global market by creating lasting partnerships in Northern Italy and Europe. The quality of the products comes from the strong manual component that characterizes all stages of the production chain: each product is made by hand, using high-end artisanal techniques, to become, after numerous steps and checks, an exclusive object. The workshop pursues this mission in an ethical and responsible manner, and with respect for the environment. This guarantee of quality, combined with a real awareness of current ecological issues, particularly made us want to collaborate.

Shoe making

Based on the design, the pattern maker creates the pattern for the various parts that will make up the shoe. Using punches, the cutter cuts out, manually or with a press, the different parts of the model from the chosen material. The pieces must be carefully cut to avoid natural defects in the leather. The parts making up the upper - the top of the shoe - are then sewn together. The internal reinforcements and counters are sewn or glued. The upper is then placed on a mold, varying according to the size, to be attached to the inner sole. Depending on the model, the sewing, gluing, sanding, and drying operations follow one another. Finally, the leather outsole is attached, first by gluing, sometimes by stitching. After a drying time, the shoe is assembled. The mold is then removed from the shoe. The final touch is the attachment of the insole, which is the visible insole, on which the foot rests. Finally, the shoe is polished to ensure an impeccable finish. Wrapped in tissue paper, the shoe is delicately placed in its JULES & JENN box. All that's left is to slip your feet inside.

At a collection point from €25

Available in 3X, 4X

100 days to try

Email, phone