The sandal-making workshop, Italy (Florence)

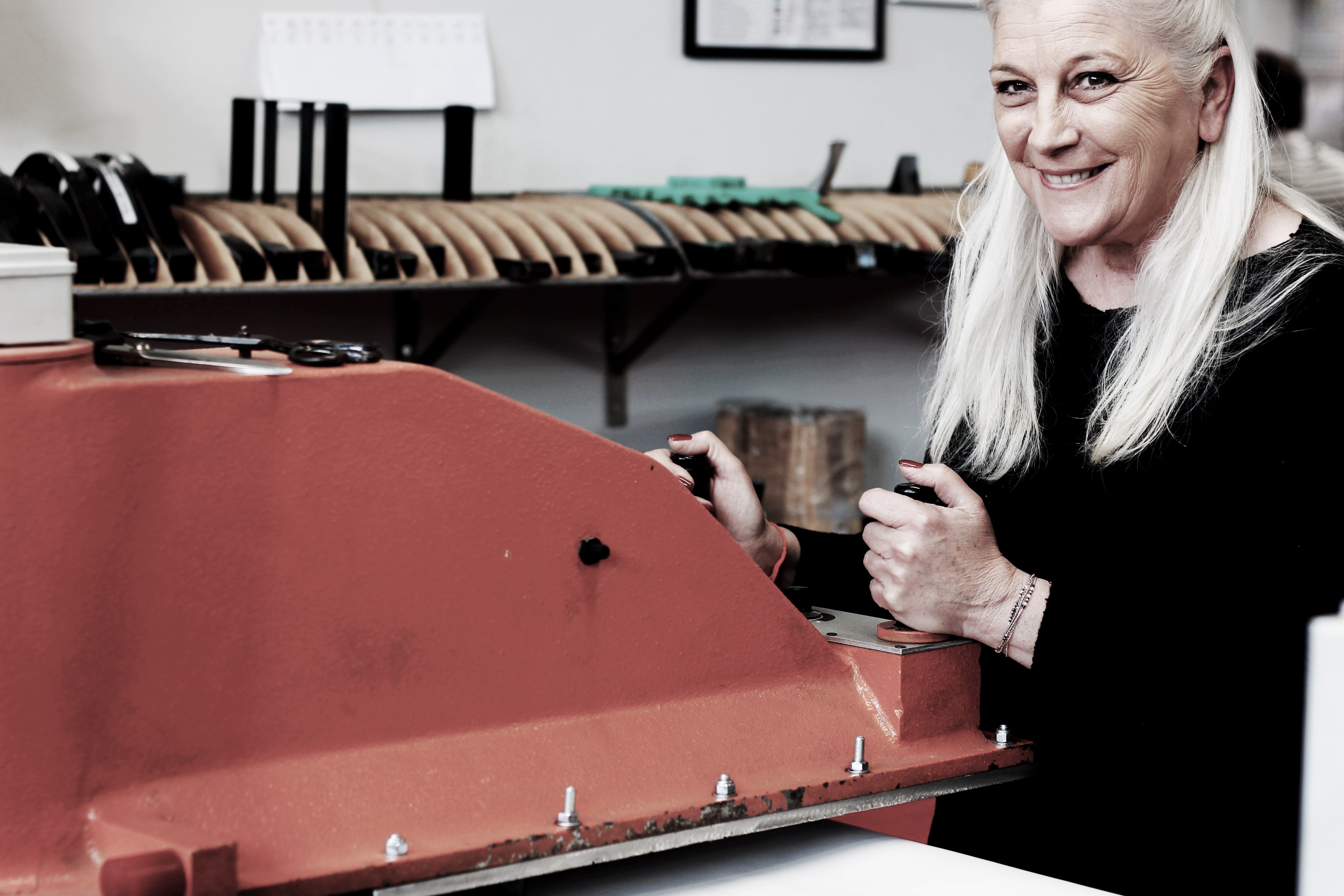

Founded in the 1960s by the current owner's father, this shoe workshop specializes in leather sandals. Nestled in the heart of the Tuscan hills, it coordinates a network of satellite workshops, in keeping with the Italian tradition that still endures for all the great Italian houses. This workshop demonstrates undeniable organization and perfect mastery of the manufacturing stages. The presence of rather young employees alongside highly experienced craftsmen explains its success in passing on the know-how of the elders to the younger generations. Thus, this workshop reflects dynamism and professionalism.

The workshop and JULES & JENN

Tuscany, a traditional sandal-making region in Italy, is the perfect place to find a partner workshop. In addition to its idyllic landscapes, leatherworking is an integral part of the local heritage.

Recommended by one of our workshops in Portugal, we were quickly won over by the dynamism and professionalism of this Italian workshop. Hidden in a cul-de-sac at the foot of a hill near Lucca, our first visit immediately inspired us to work together. Several back-and-forths and exchanges allowed us to develop a collection of sandals with a timeless style and high-quality finishes.

Coming back to see them to discuss materials, models or production progress allows us to improve our models and work hand in hand.

Shoe making

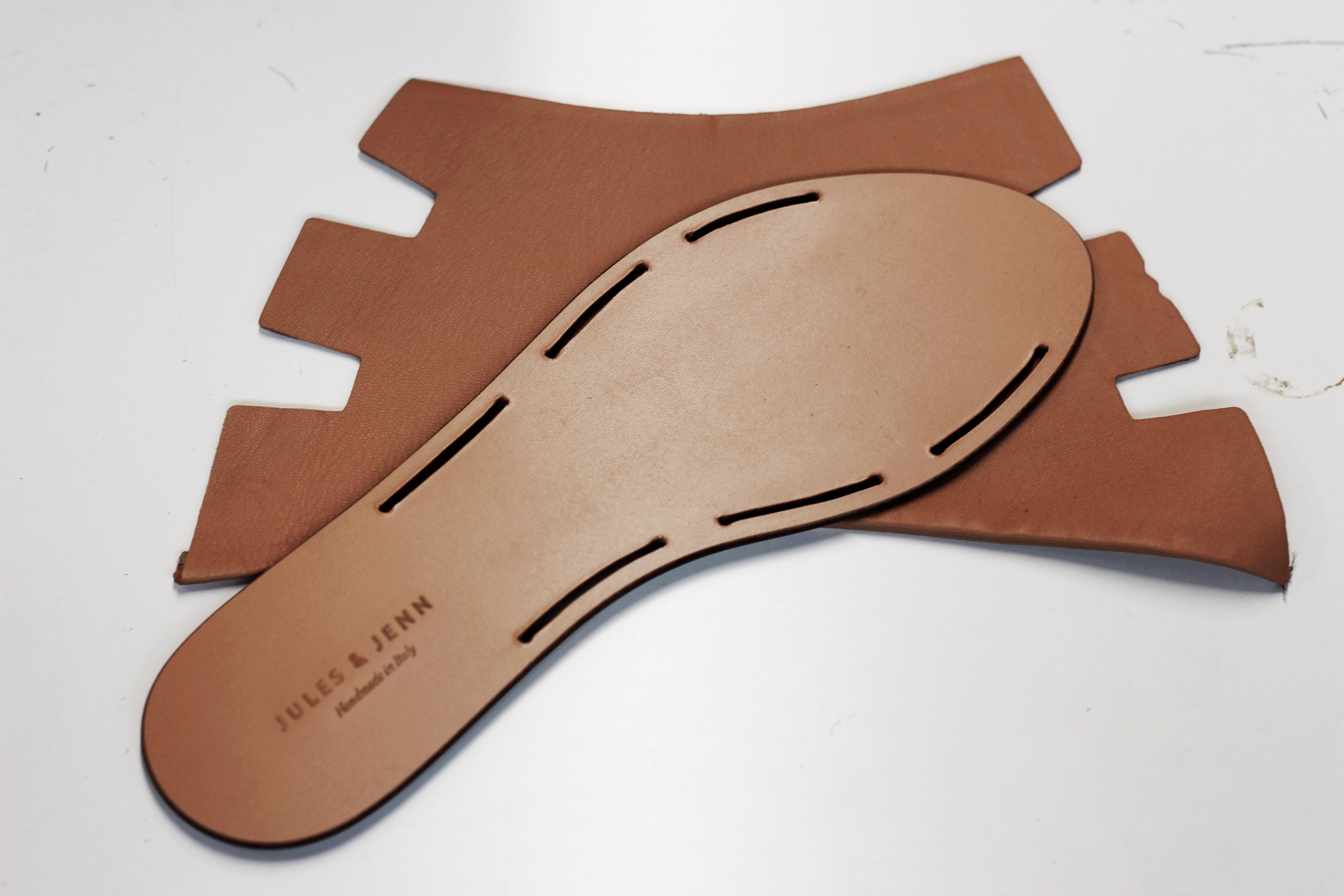

Based on the design, the pattern maker creates the pattern for the various parts that will make up the shoe. Using punches, the cutter cuts out, manually or with a press, the different parts of the model from the chosen material. The pieces must be carefully cut to avoid natural defects in the leather. The parts making up the upper - the top of the shoe - are then sewn together. The internal reinforcements and counters are sewn or glued. External decorations are also added. The upper is then placed on a mold, varying according to the size, to be attached to the inner sole. Depending on the model, the sewing, gluing, sanding, and drying operations follow one another. Finally, the leather outer sole is attached, first by gluing, sometimes by sewing. After a drying time, the shoe is finished. The mold is then removed from the shoe. The final touch is the attachment of the insole, which is the visible insole, on which the foot rests. Finally, the shoe is pampered to smooth out any remaining imperfections. Adorned with tissue paper, the shoe rests in its JULES & JENN box. All that's left is to slip your feet inside.

At a collection point from €25

Available in 3X, 4X

100 days to try

Email, phone