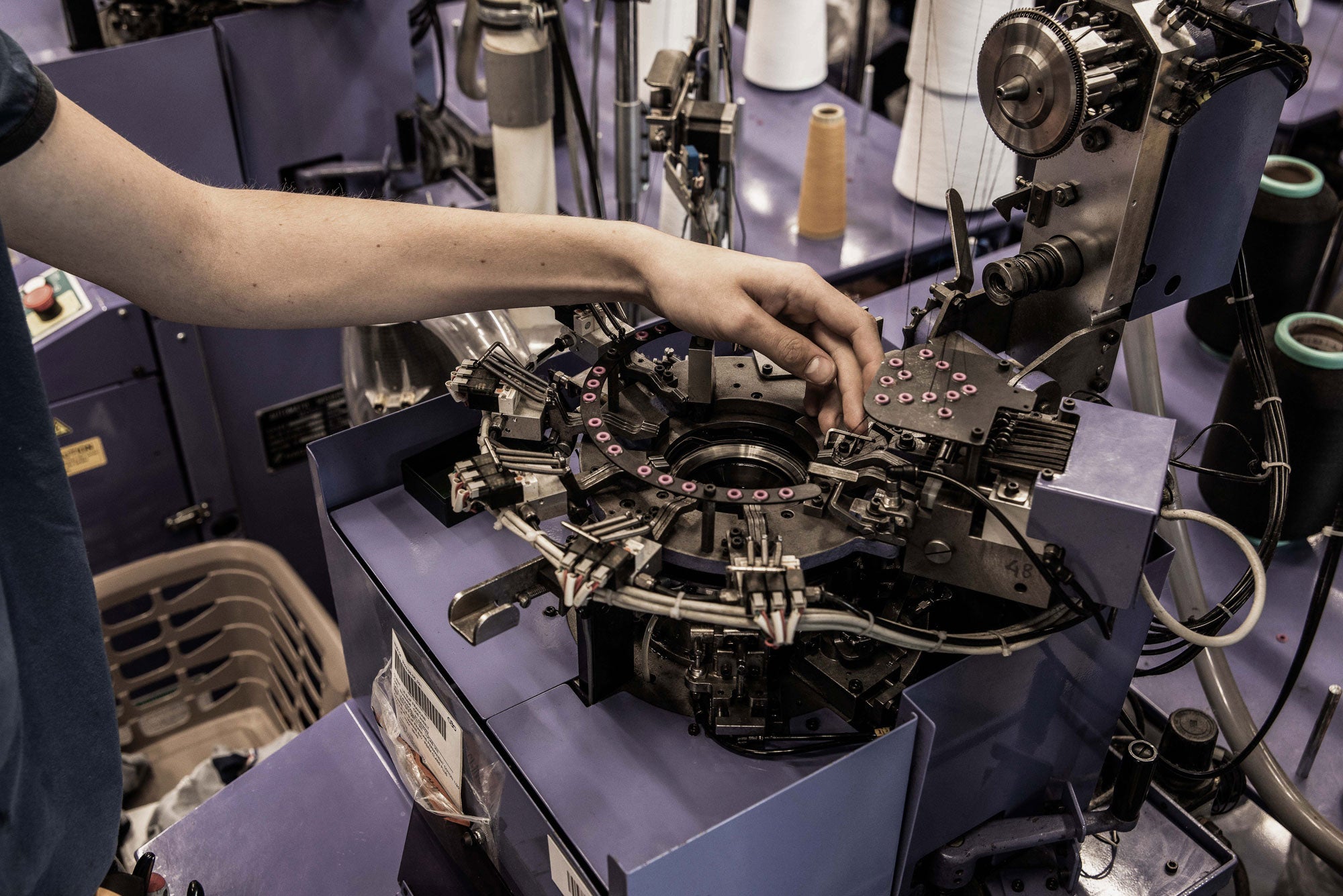

The sock manufacturing workshop, France (Limoges)

This Limousin company was founded in 1938. At that time, a young married couple embarked on an entrepreneurial adventure by creating their sock workshop, which would eventually employ more than 200 people. Over successive generations, the factory saw the introduction of electronic machines in the 1980s, allowing for faster production. Since the 2000s, the founders' grandchildren have continued to transform the company with the arrival of new, innovative methods! Without ever moving, the workshop has modernized its production site while remaining faithful to its roots.

The workshop and JULES & JENN

The workshop has made quality its trademark, a know-how recognized by the Entreprise du Patrimoine Vivant (EPV) label. Entirely made in France, their socks express a certain idea of style and trend: we wear them like true fashion accessories that highlight our unique personality. By remaining faithful to the heritage of its beginnings, our partner workshop has managed to preserve its quality, while continually evolving its manufacturing techniques! Particularly attentive to the environmental and social issues of our time, the workshop where our socks are made guarantees fair and respectful working conditions for its employees. Its environmental footprint is also at the heart of its thinking. Thus, all sock waste is recycled and transformed into a new yarn that will be used to design new socks. It is these commitments, as well as the great accessibility of the teams, that particularly appealed to us and that allowed the launch of this new partnership.

The making of the sock

Based on the design, the designer exports the sock sketch to software. The thread colors are selected and the machine is set according to the desired result. The threads are then knitted together for about 4 minutes to create the body of the sock, which at this stage resembles a cotton tube with a heel. It is then passed over a tube to turn it inside out. Then comes the remeshing stage, which consists of sewing the tip of the foot with a dedicated machine. To give the sock its final shape, it is placed on a flat foot-shaped support. Passed through a steam machine, it comes out with its stitches tightened. Finally, the sock is manually checked to verify that each pair is identical, in the right color, with the same stitch and with all the threads pulled. The sock is then slipped into its 100% recyclable plastic bag. All that's left is to slip your feet inside.

At a collection point from €25

Available in 3X, 4X

100 days to try

Email, phone